Optimization

of quarry processes

Glass-Link stands as a reliable, long-range wireless communication solution for Industry 4.0. It harvests data from nodes equipped with sensors, and sends it directly to the customer's IT systems, enabling data collection and analysis.

Glass-Link also facilitates the digitization of existing electromechanical or mechanical infrastructures. This enhancement allows for the remote retrieval of data from sensors lacking direct access to a digital link.

Case Study

The Glass-Link Gateway has been installed on a mast located in a quarry, which collects information from the Glass-Link Nodes distributed over an area of several square kilometres.

The quarry is located in a remote area with harsh weather conditions.

Water flow at the pump station monitored by the Glass-Link Node.

The Glass-Link Node, integrated with equipment on the industrial site, transmit real-time information about the status of the infrastructure.

Installation of an antenna on the monitored vehicle.

Glass-Link Node installed on the vehicle to monitor its position and operational status.

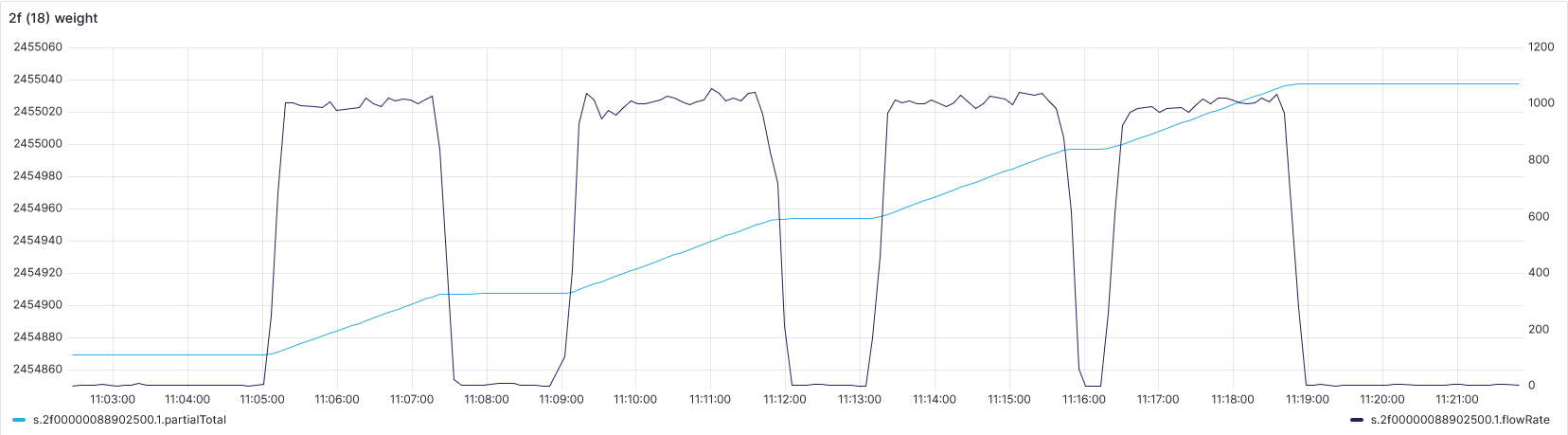

This includes the position and operational status of vehicles, water flow, energy meters readings, and parameters of the excavation of the ore on the conveyor belts—its weight and speed over time (see graph).

Accumulated mass of mined material on the conveyor belt and its flow over time.

Conclusions

Thanks to the data provided, the quarry's management gained a detailed insight into the key parameters of the site's operation, analyzing electricity and fuel consumption in relation to the weight of ore extracted.

The analysis of the data made it possible to identify anomalies and effectively eliminate bottlenecks.

The analysis of the data made it possible to identify anomalies and effectively eliminate bottlenecks.

Glass-Link, as a private and secure wireless communication network, has made the company independent of external communication operators, both operationally and financially.

Glass-Link has increased the company's productivity and operational efficiency, reducing operating costs and increasing the security and safety of both staff and equipment.

Glass-Link has increased the company's productivity and operational efficiency, reducing operating costs and increasing the security and safety of both staff and equipment.

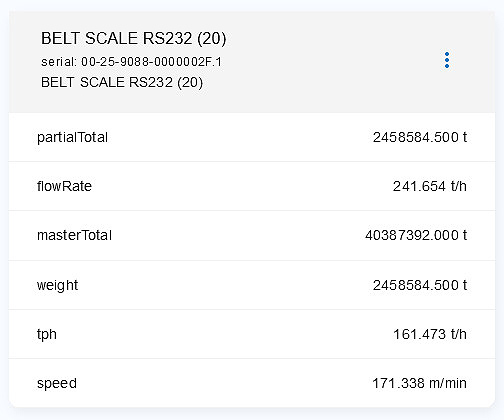

Real-time status of ore weight and transmission on the conveyor belt.

Industry digitization simplifies management.

Profit in Sustainability

At the forefront of a sustainability-driven operations model, Glass-Link's monitoring plays a pivotal role in elevating productivity within the mining industry, fostering environmental improvements, and at the same time reducing production costs.

2024's trend: Prioritize smart sustainability and better management with Glass-Link's IIoT technology for a greener, business-driven future of your industry.

Explore our presentation to discover how our innovative IIoT solutions can revolutionize your industry:

Download PresentationCONTACT US

FOR MORE INFORMATION:

info@glass-link.ie

FOR MORE INFORMATION:

Pilot with Glass-Link!

Test our IIoT solutions in a controlled setting and experience the benefits of Glass-Link powerful products firsthand in your operational environment in 𝟯 𝗷𝘂𝘀𝘁 𝗲𝗮𝘀𝘆 𝘀𝘁𝗲𝗽𝘀!

Read more